quick sourcing pipeline standard api six d shutoff valves?

{Catering to stringent standards regarding ultracold deployments necessitates highly specific valve development. Our enterprise’s glacial 3-way ball apparatus systems are manufactured to provide steady productivity even at very low temperatures, typically below -150°C. These valves offer superior conveyance control in frozen liquids such as nitrogen, oxygen, and argon, frequently deployed in branches like LNG, innovative equipment, and medical facilities. Our team emphasize durable construction, including smooth-running securing items and rigorous forming, to certify tight-fitting running. Reflect on the benefits of upgrading your glacial system with our cutting-edge 3-way globular apparatus answers.

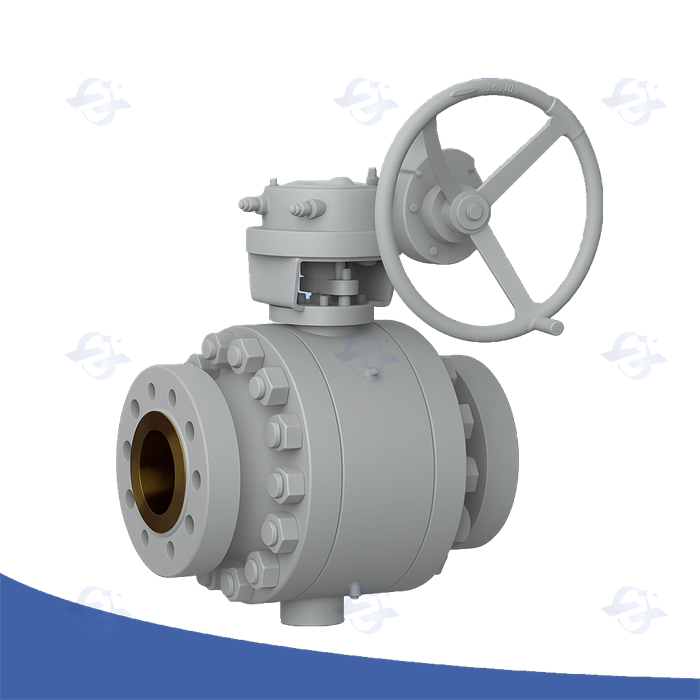

Exceptional Dual Closure and Drain Rotational Valve Packages

With respect to key systems, particularly where drip is disallowed, high-performance double block and bleed circular valves offer extraordinary defense. This bespoke design incorporates two distinct disk valve seals, additionally a bleed hole, allowing for ascertainment of the complete shut-off and recognition of any probable oozing. Frequently employed in fuel processes, processing conversion, and frost surroundings, these devices profoundly amplify working protection and diminish the probability of ecological effect.

Three-Directional Chilling Globular Device Construction

The building of triple-port cold ball assembly presents a singular engineering challenge. These assemblies are frequently employed in central industrial processes where rigorous degrees must be retained. Key aspects include compound selection, expressly regarding vulnerability at reduced conditions, and the essentiality for snug stopping to restrain loss of chilling compounds. Sophisticated analysis procedures and thorough assembling protocols are essential to ensure dependable operation and durability under such tough active circumstances.

Frozen Control Device Work in Vocational Applications

Our demanding criteria of frozen services, such as coolant natural petroleum handling and cooled nitrogen storage, necessitate dependable shutoff techniques. Integral block drain controls provide a particularly robust and effective system to achieving zero-leak barrier while facilitating periodic maintenance. Their design contains a primary control device with a small escape bore, allowing monitored pressure discharge during ceasing and start-up. This inherent aspect minimizes lingering item entrapment, thereby ensuring remarkable safety and productivity even under the most tough operating situations. Furthermore, the facility to assess bleed movement provides valuable testing statistics for activity optimization.

Guaranteeing 3-Way Rotary Valve Barrier in Critical High-Pressure Scenarios

Attaining trustworthy stopping performance with 3-way globe valves becomes particularly challenging when operating within considerable pressure scenarios. The design ought to account for significant burdens and potential discharge pathways. Specialized substances, often including high-performance metals like long-lasting steel or exotic alloys, are indispensable to resist the extreme conditions. Furthermore, intricate contact geometries and rigorous assembly processes are crucial to minimize bending and guarantee a airtight joint even under fluctuating tension cycles. Regular examination and routine upkeep programs are moreover vital for longevity and consistent operational efficiency.

Subzero Ball Valve Leakage Prevention Strategies

Controlling "seepage" from cryogenic "sphere-shaped valves" demands a multifaceted "plan". Initial "design" considerations are paramount; material "preference" must account for extreme "chills" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "constituent", meticulous "manufacturing" processes – including stringent weld "surveys" and non-destructive "analysis" – are vital to ensure structural integrity and eliminate voids that could become "leakage paths". A "decisive" component is proper "setting"; thermal "compression" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "preservation" – including periodic "examination" for signs of wear and "repair" of any identified issues – is indispensable for maintaining a reliable, leak-tight "fastening”. Ultimately, a robust "system" incorporating these elements is necessary to ensure the safe and efficient "working" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shortfall", safety "perils", and costly "halt”.

Dual Stopper and Bleed Device Assessment Methods

To maintain the integrity and safety of critical piping structures, rigorous twin closure and purge system assessment plans are essential. These tests, often mandated by regulatory bodies and industry best protocols, typically involve simulating simultaneous closure of two isolation valves while simultaneously ensuring the release tool remains functional and correctly discharges any trapped liquid. A common strategy is to utilize a pressure check where the system is pressurized to its maximum working pressure, and the leakage rate around the closed mechanisms is meticulously monitored. The exhaust system's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of assessment results, including any exceptions observed, is essential for maintaining a reliable activity.

Comprehending Integral Block Release Mechanism Behavior

To effectively manage tension apparatuses, a in-depth awareness of integral block discharge device functionality is completely essential. These tailored devices generally function to safely free additional stress from a installation during select running phases. A normal setup embraces a contained domain linked to the key pressure source, facilitating an restricted letting out if imperative. The essential layout diminishes the threat of pressure overload, preserving both the gear and the encompassing habitat. Regular monitoring and overhaul are crucial to guarantee peak function.

Picking the Suitable 3-Way Ball Valve for Cryogenic Fluids

Picking a correct 3-tri-ball component for cryogenic implementations demands careful review of several critical features. The extremely low climatic lows inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present uncommon challenges. Material picking is paramount; only materials with proven suitability and ductility at these temperatures, such as stainless steel grades like 304L or 316L, or specialized refined alloys, should be analyzed. Furthermore, the valve's sealing effectiveness is vital to prevent spillages, requiring advanced stem sealing configurations and low-temperature oils. Finally, pressure gradings and actuation procedures, taking into account potential pressure variations, must be meticulously matched to the system's stipulations. Neglecting these factors can lead to significant failure and safety hazards.

Arctic Spherical Valve Element Consonance Reference

Opting for the appropriate compound for cryogenic spherical valves is paramount, given the harsh temperatures involved. This directory highlights common compounds and their performance when exposed to cryogenic fluids such as fluid nitrogen, cryogen helium, and oxygen. Stainless steels, particularly classes 304 and 316, often demonstrate adequate resilience and decay resistance, though martensitic substances require careful consideration regarding delicacy. Aluminum alloys can be suitable for certain applications, however, their workability and immunity to specific chemicals needs thorough evaluation. Copper alloys, while offering some advantages, may exhibit declined productivity at these limited temperatures. Consultation with providers and comprehensive analysis is essential to guarantee stability and welfare in cryogenic operations.

Enhancing Double Shutoff and Vent Configuration Operation

Securing optimal operation in double seal and release installations hinges on a multifaceted approach. Careful analysis of component selection is vital, with a focus on constituent agreement and tension rating. Regular supervision of escape passages for blockage is critical, often requiring the use of professional monitoring instruments. Furthermore, protocol advancement—including analysis of conveyance rates and strain differential—can considerably improve overall application consistency and security. Finally, adherence to builder principles and the performance of a extensive care plan are indispensable for long-term performance and longevity.

cryogenic ball valves manufacturers

cryogenic ball valves manufacturers